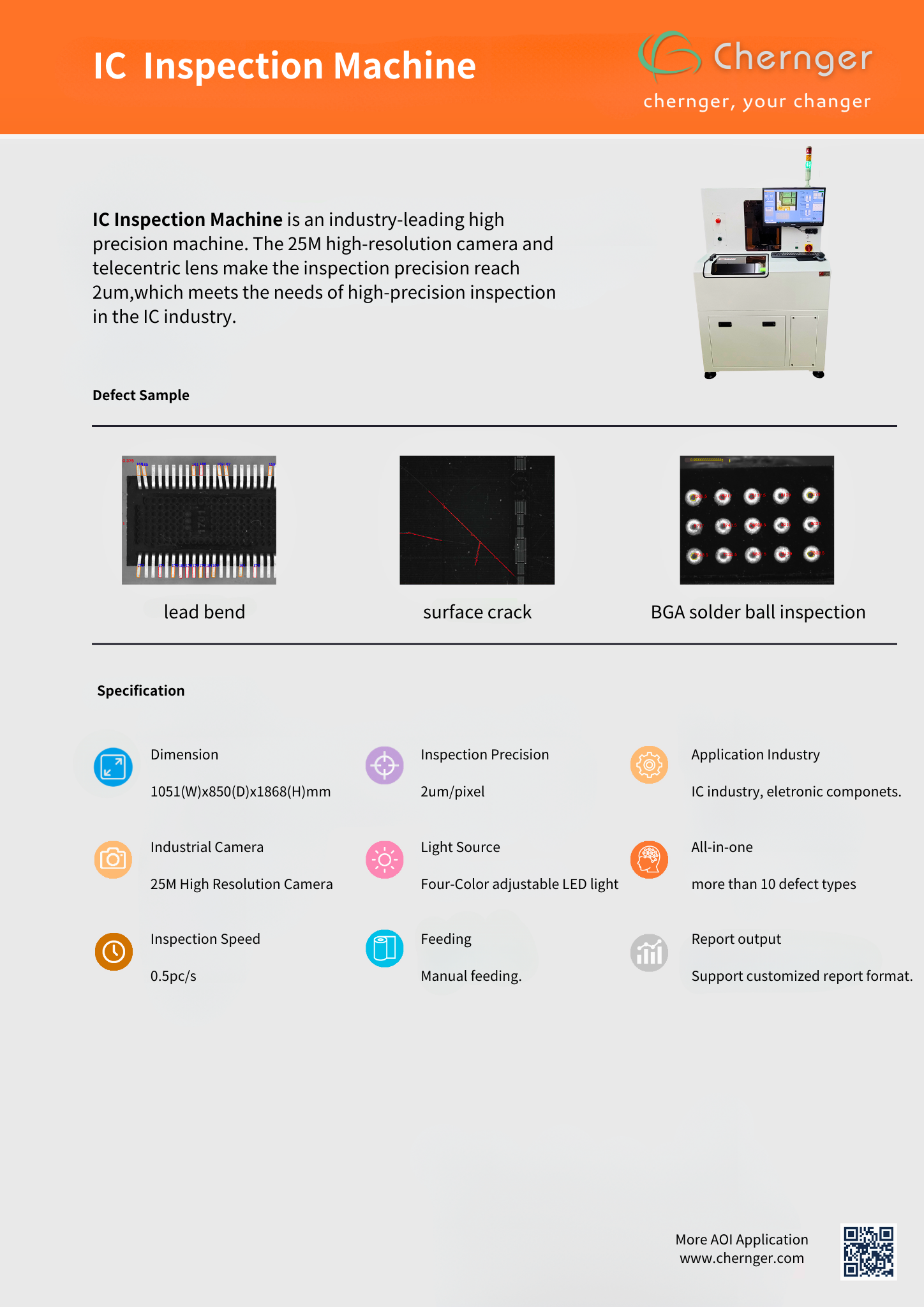

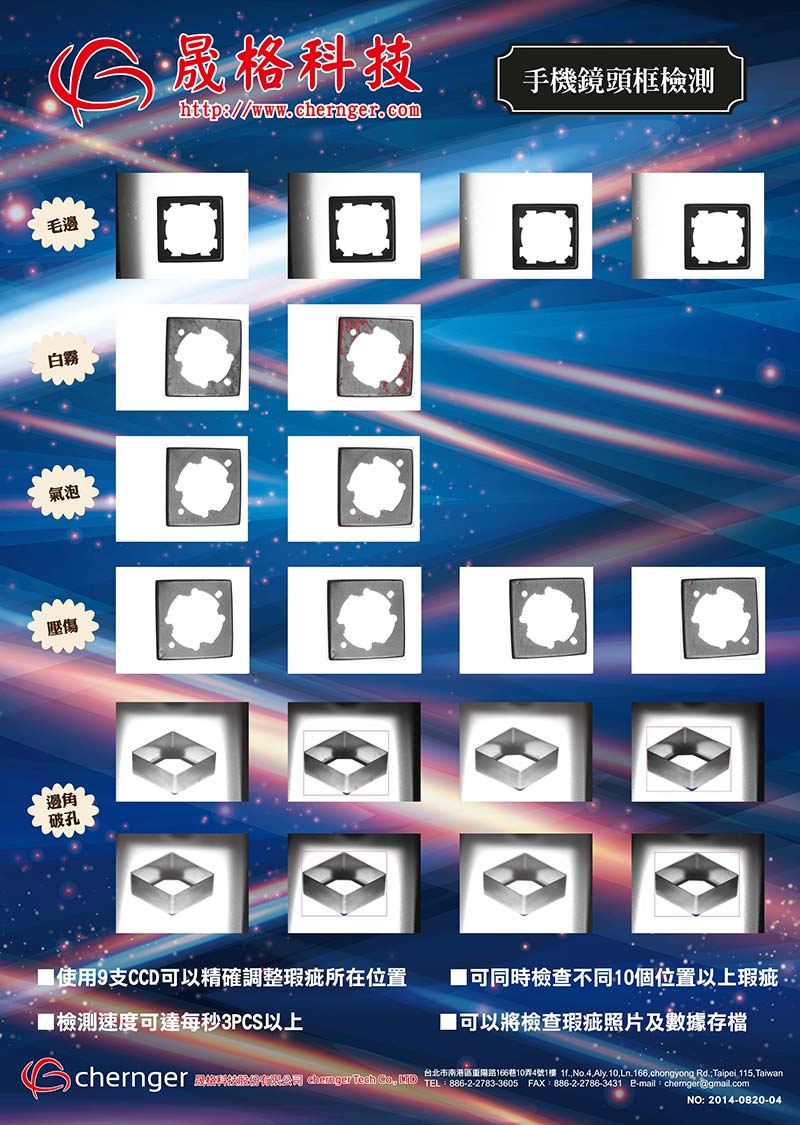

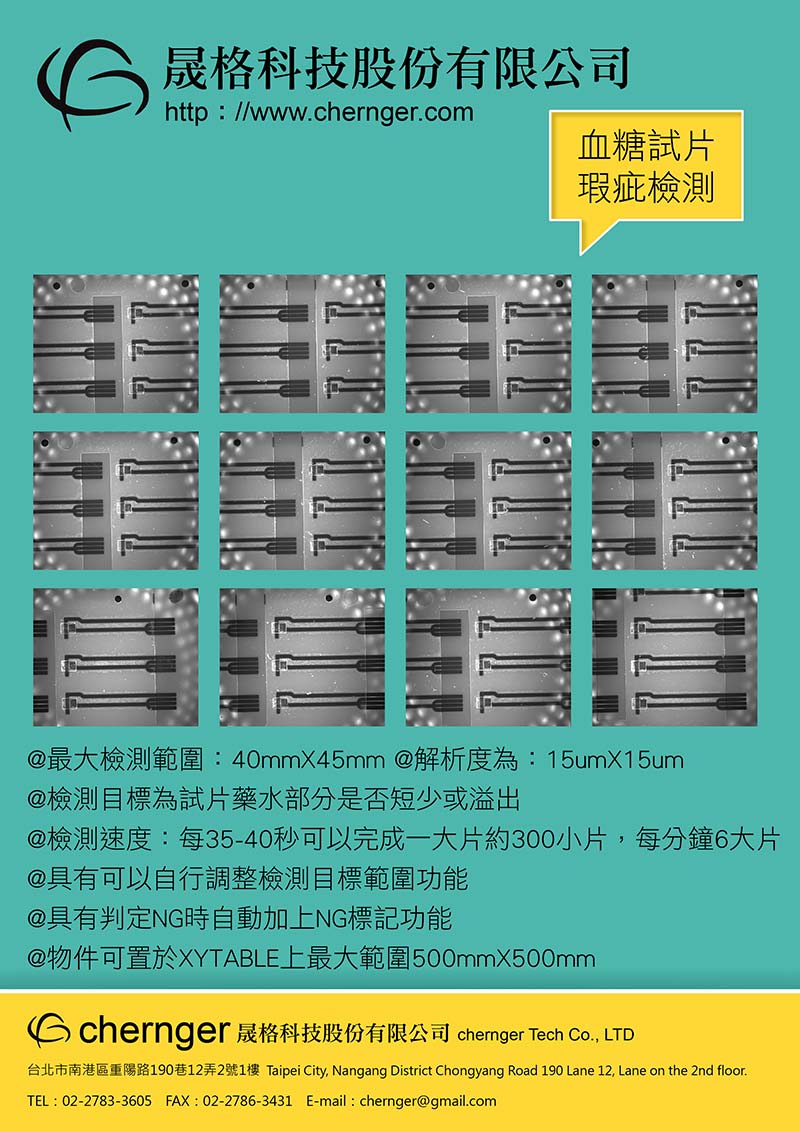

02 XY Table Inspection Machine

Features:

- High-speed and high-precision inspection.

- Multi-point synchronous inspection, Exclude defective product and recording functions.

- Summary graph.

- Machine operating authority management

Applications:

- Metal Plate, Metal Components, Plastic,

Our customers:

- 米亞(smartphone components), 晟銘(3C components), 台灣銘版(printed nameplate), 愛爾康(contact lens)

Product specifications

- High Speed: 60pcs/sec (2M)

- Machine Learning: equipped with AI automatic learning system to distinguish qualified and defective products

- Synchronous Inspection: 10 areas at the same time

- Inspection Area: 2mm2-200mm2

- Camera: 2 million to 25 million pixels industrial camera

- Accuracy: the resolution of camera with lens is 0.001mm to 0.05mm

- Defect Inspection Capability: 2M 60pcs/sec or 5M 4pcs/sec

- Record Classification: inspection data are saved in order in separate files which are named by dates.

- Photo Management: automatically generate files and create file name by date and time.

- Instant Trend Graph: can display the last 1000 data

- Operation Modes: A working mode (data only), B engineering mode (including live image), and C tuning mode

E-Flyer

Video

XY Table Inspection Machine-blood glucose test strip