06 Contact Lens Inspection System

Features :

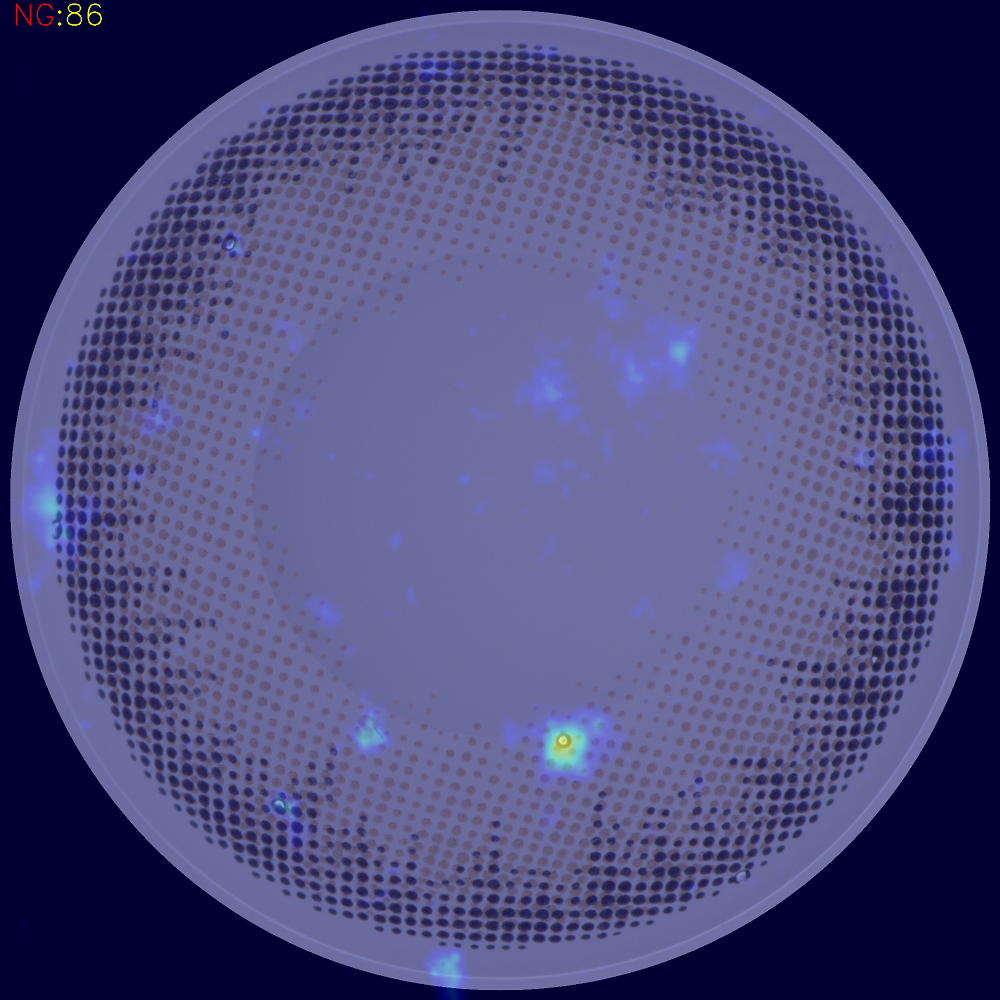

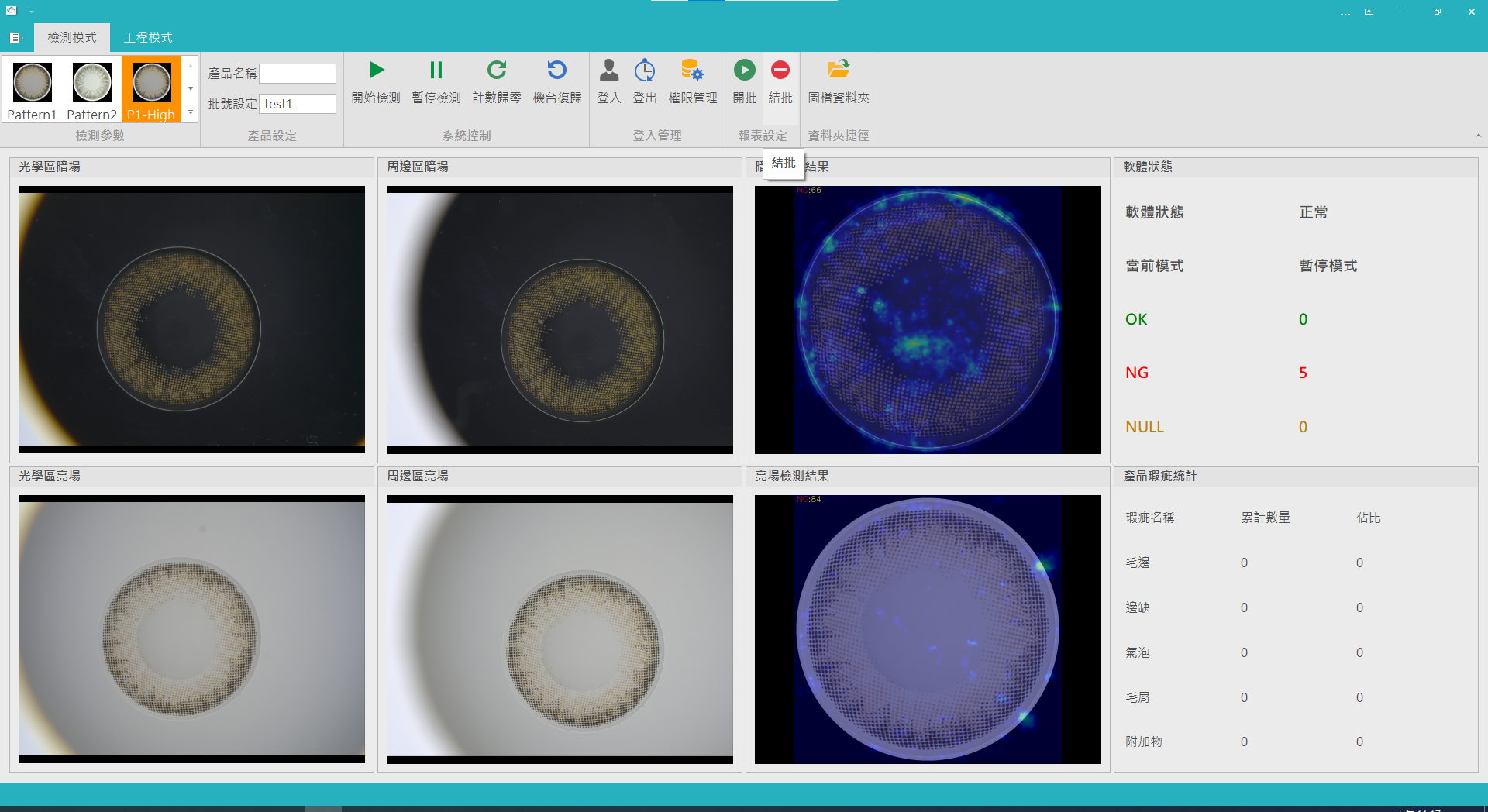

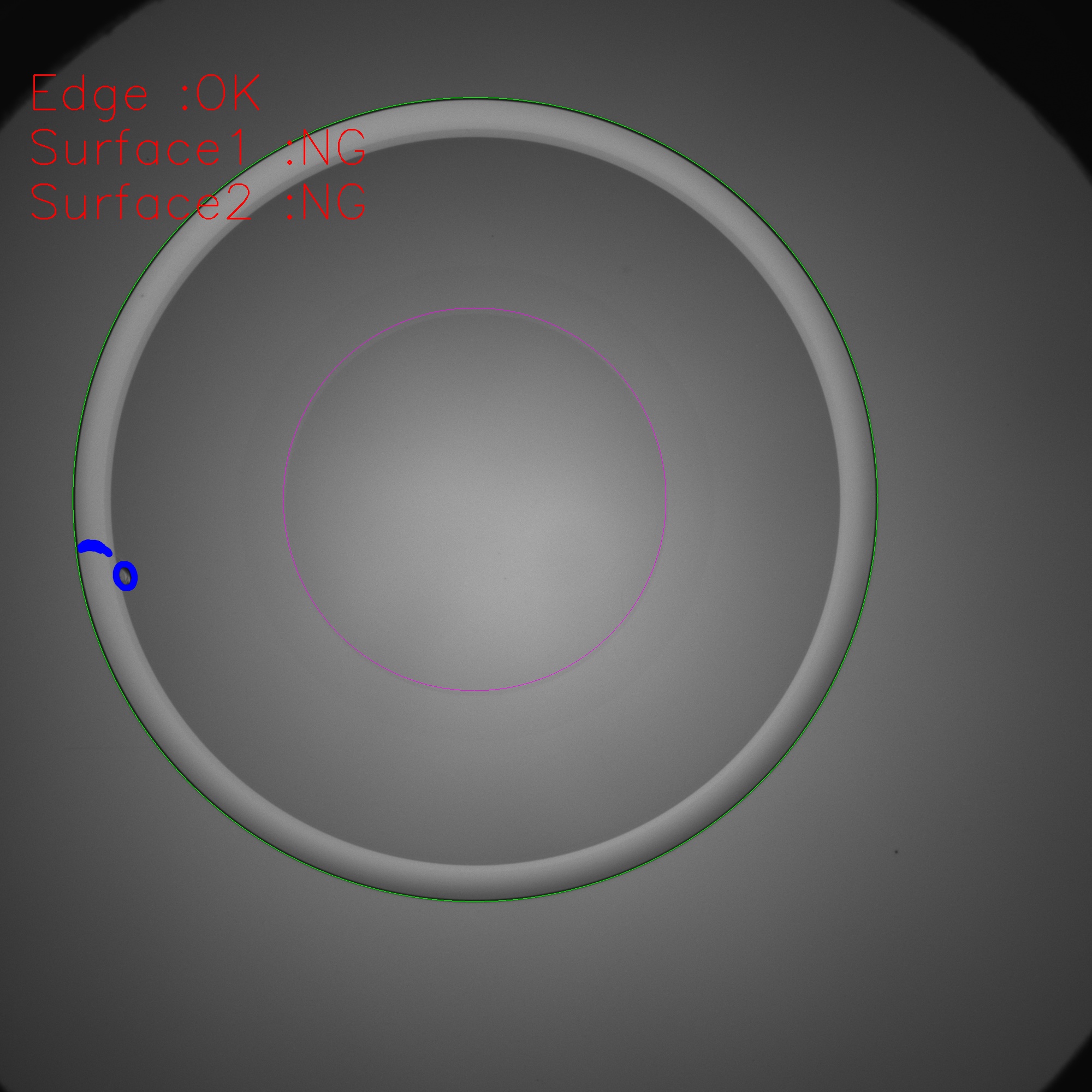

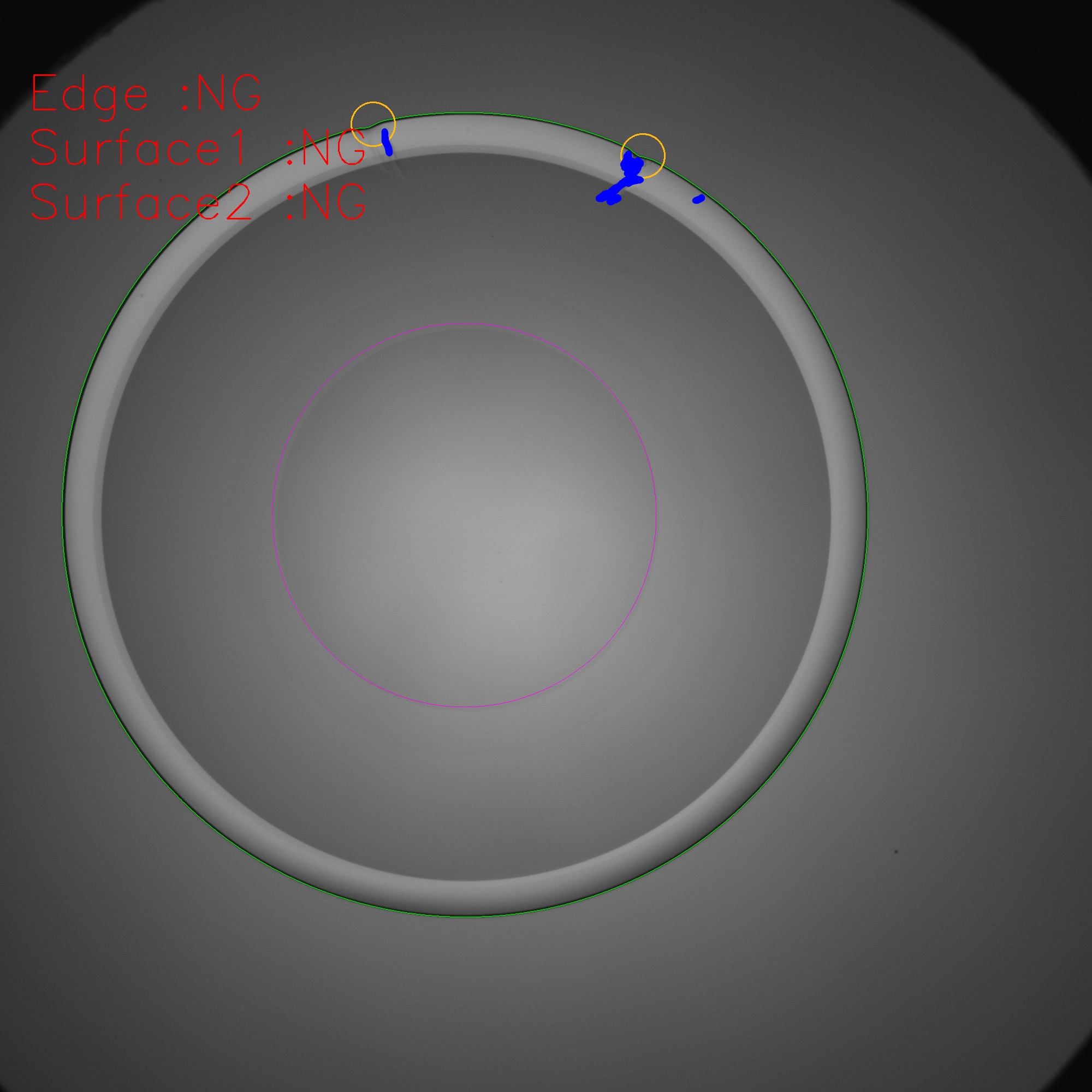

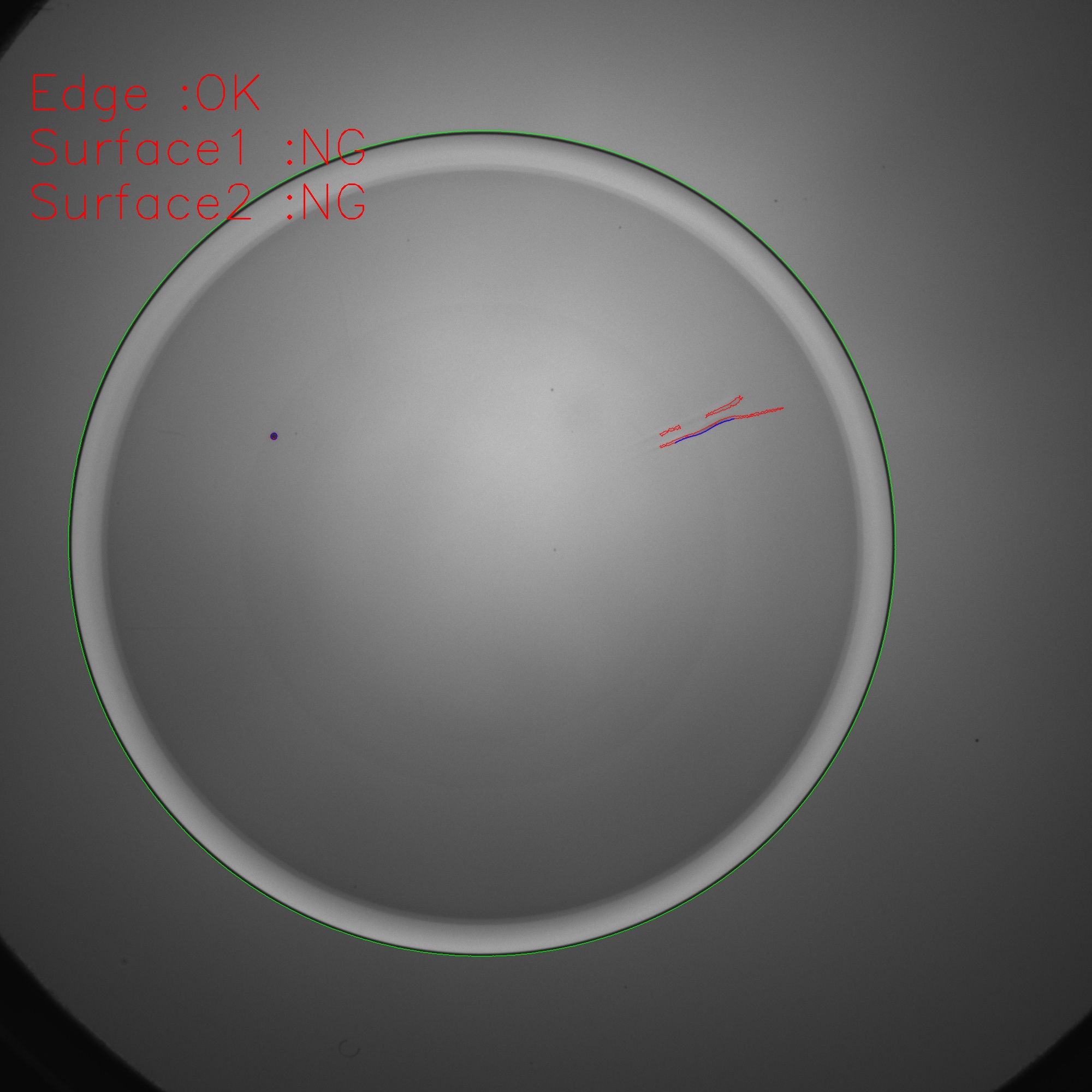

- AI learning: Through the process of ok sample learning, the defect areas will be analyzed automatically by the system, which can greatly improve the detection rate of defects.

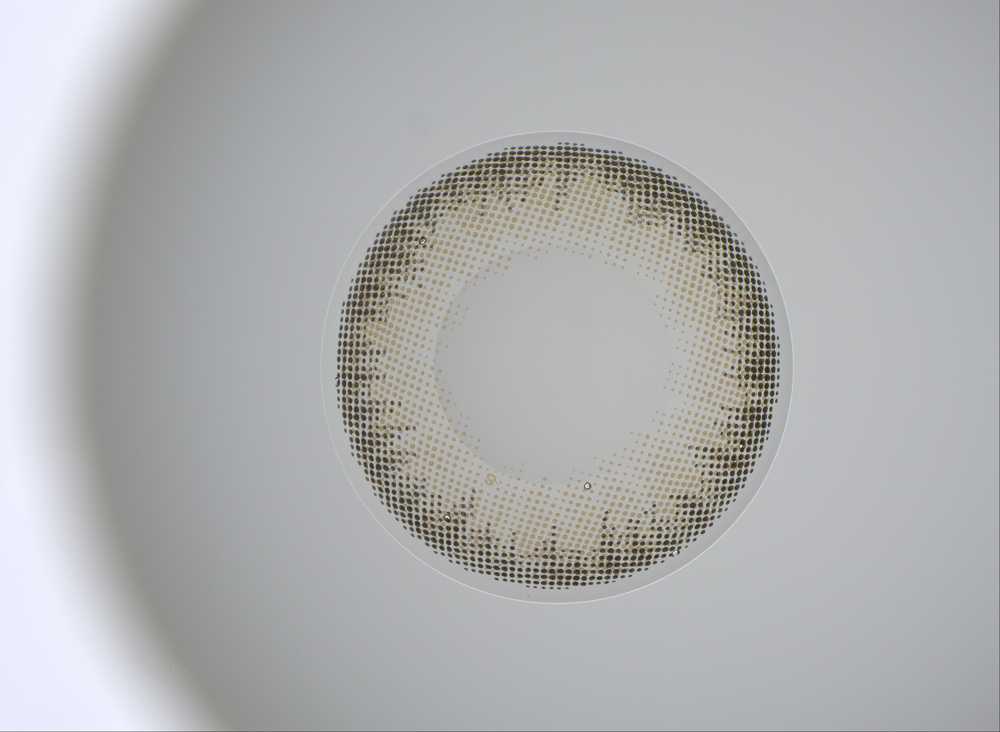

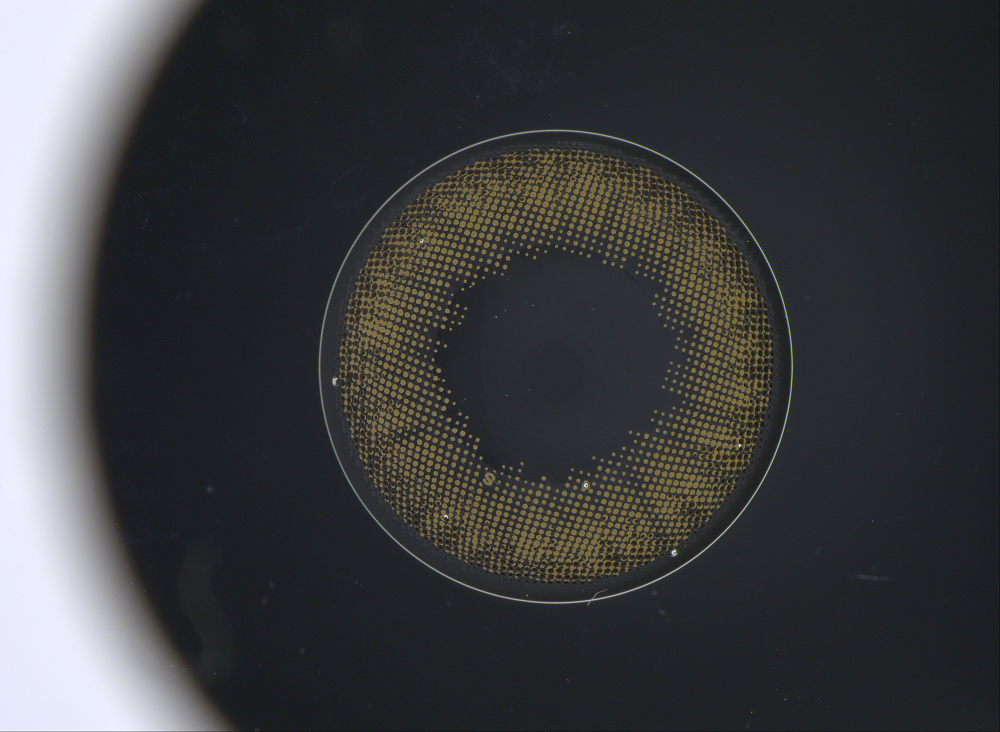

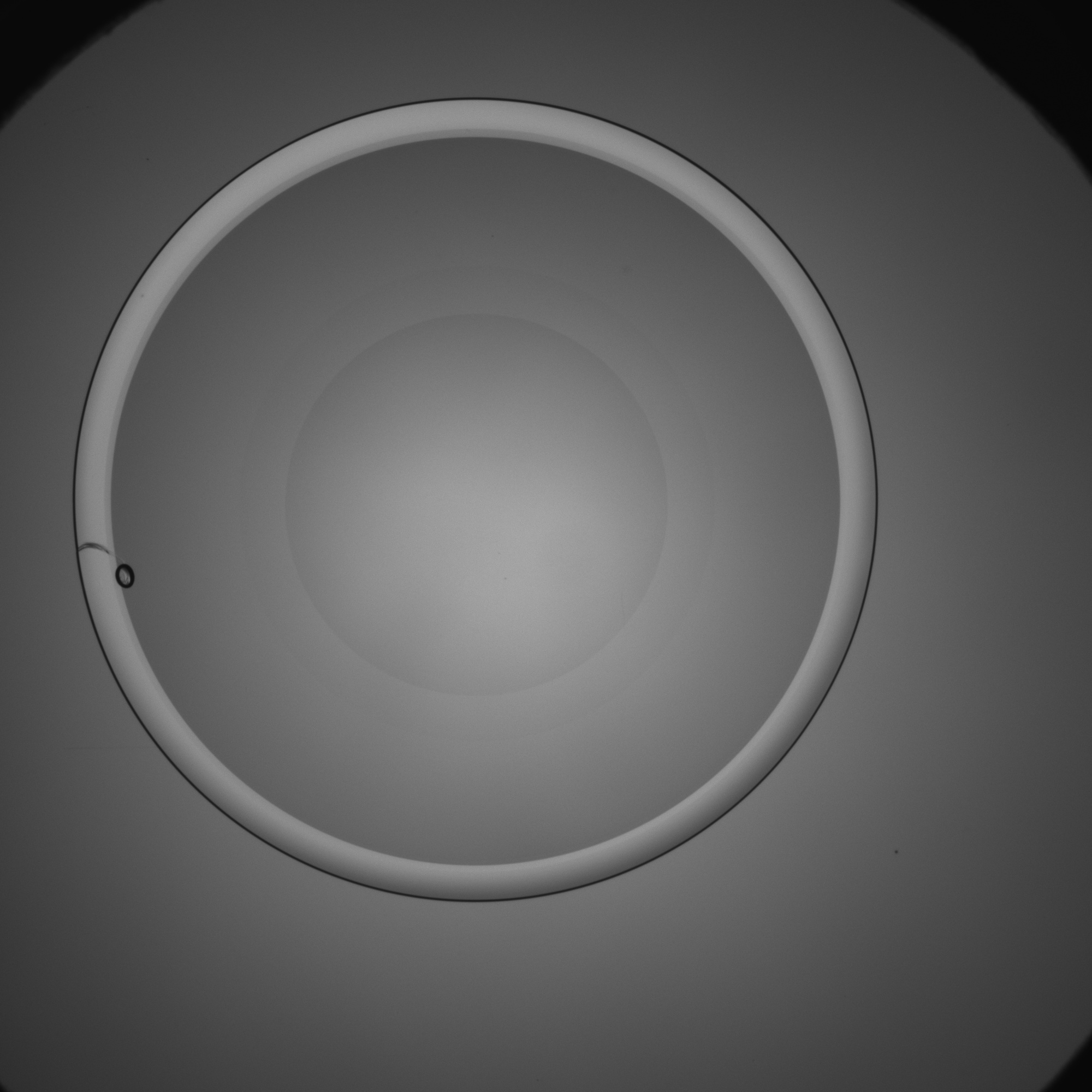

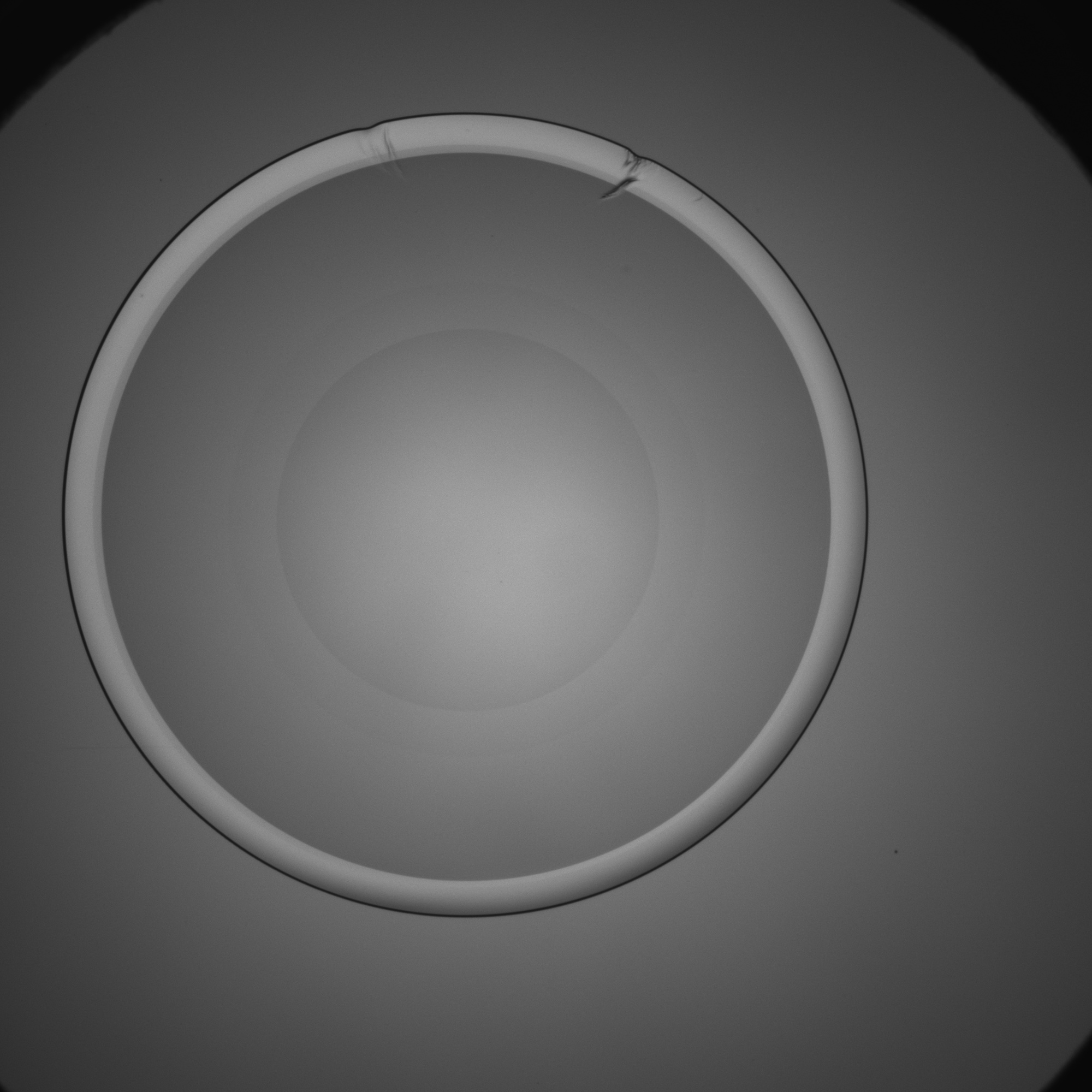

- Multi-light field detection:Through bright and dark field (two light sources), the ability to detect the pattern of the color lens is improved, so that the software can detect the defects covered by the pattern.

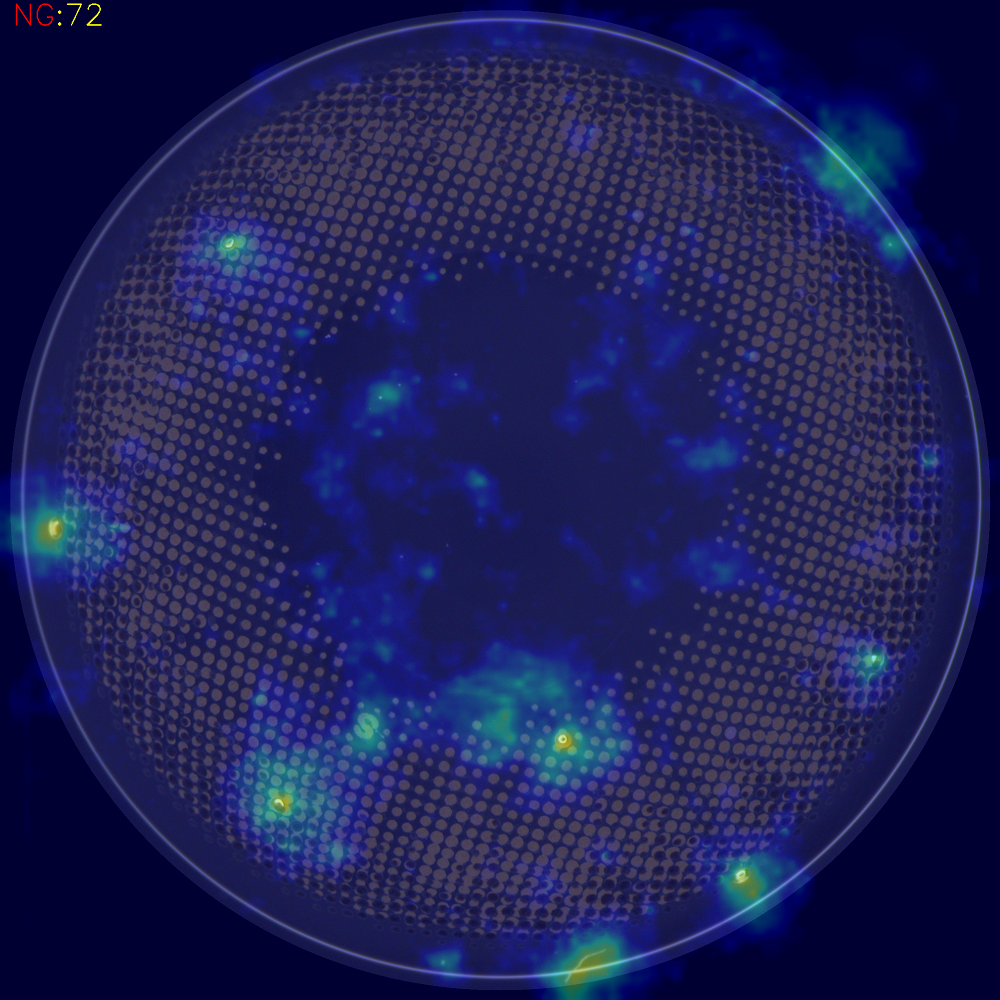

- Heatmap analysis: Through heatmap analysis to distinguish defects' locations and severity, the operators could simply guage the verification results 。

- Classified defects function: AI can be used to train pictures with different type defects, and it classifies different type of defects into categories, so as to facilitate production line personnel to analyze production conditions。

- Report function: Every closed batch generates a production report which includes all inspection results, production yield, defect ratio and other data。

- Alert function: Capability of NG quantity settings, auto-shutdown and alert the operators, handling unusual situation or emergency。

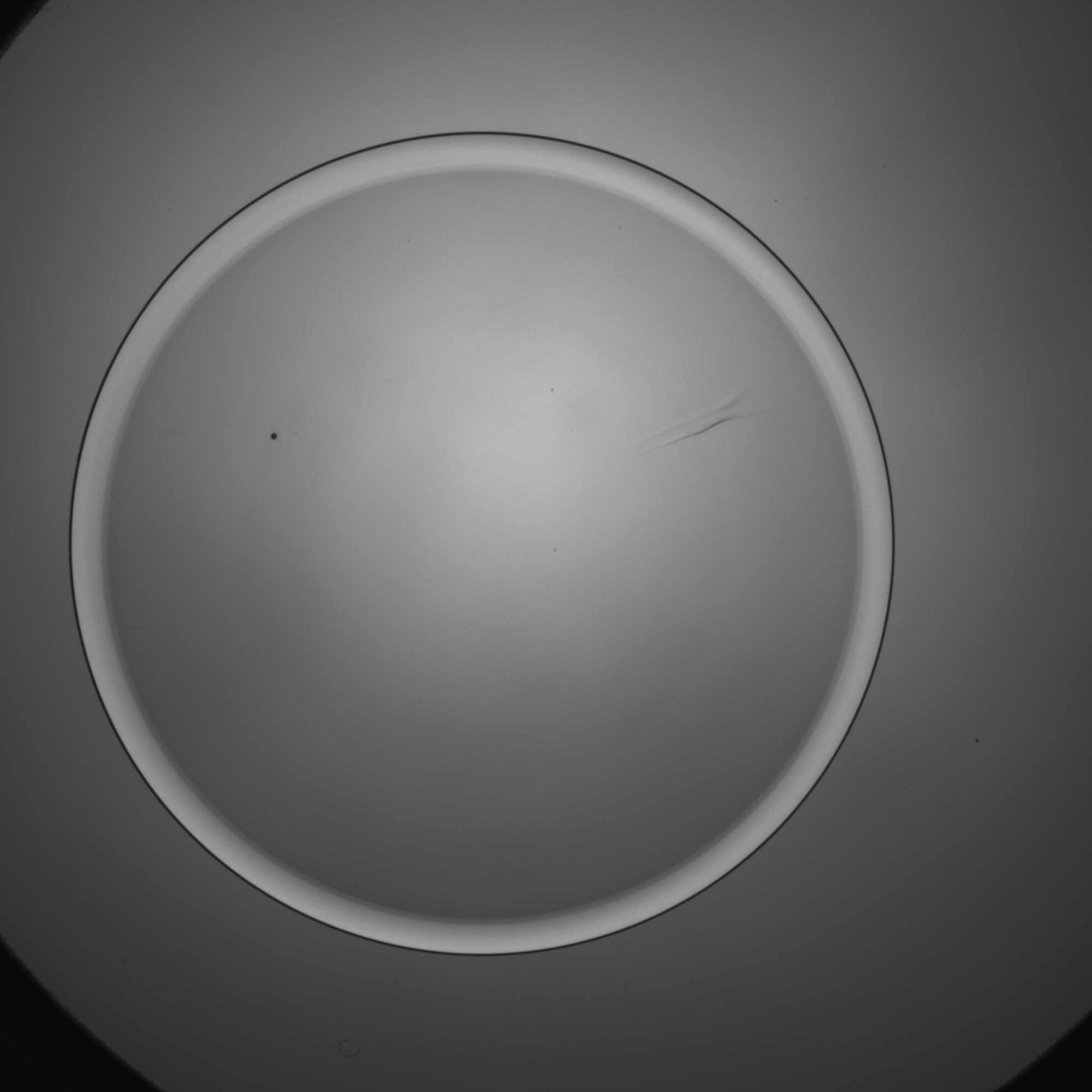

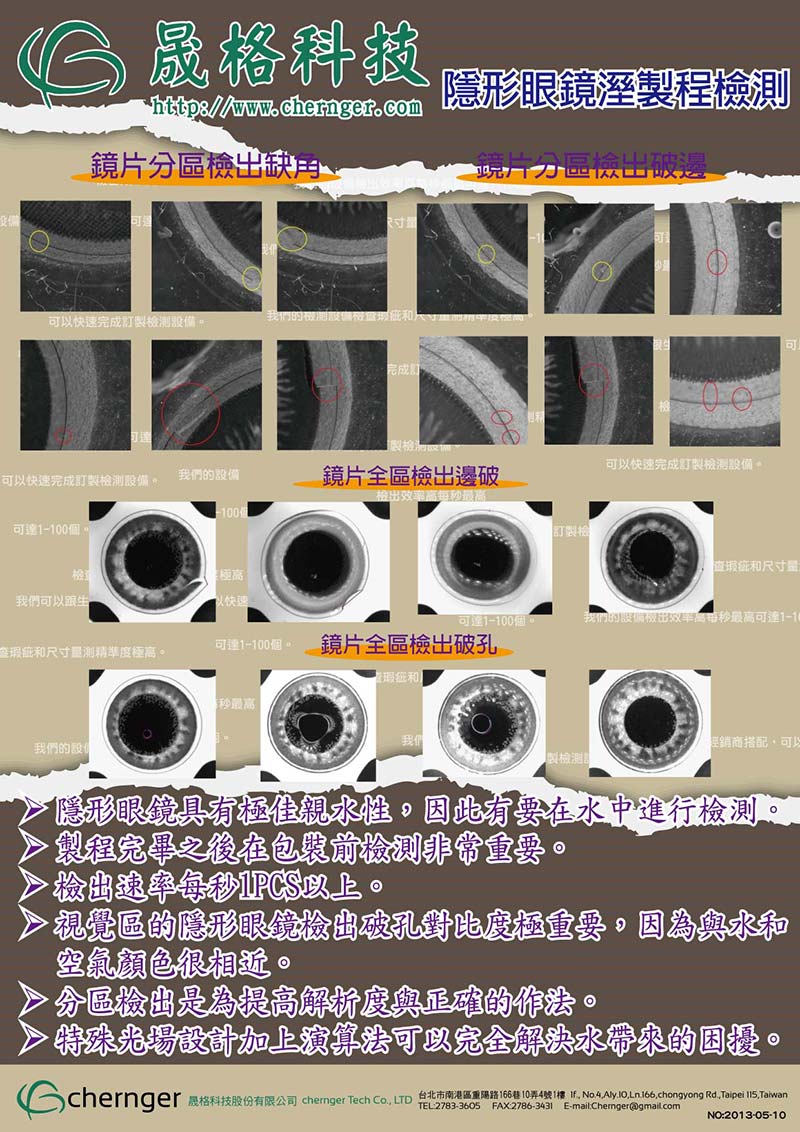

- This system can detect the following defects and conditions: Edge loss, burrs, air bubbles, additional material, dander, lack of ink in the pattern, partial printing of the pattern, cracks and other defects。

Industry applied

- Contact lens and mold defect detection

- Wet and dry process inspection

- Appearance inspection of contact lens packaging

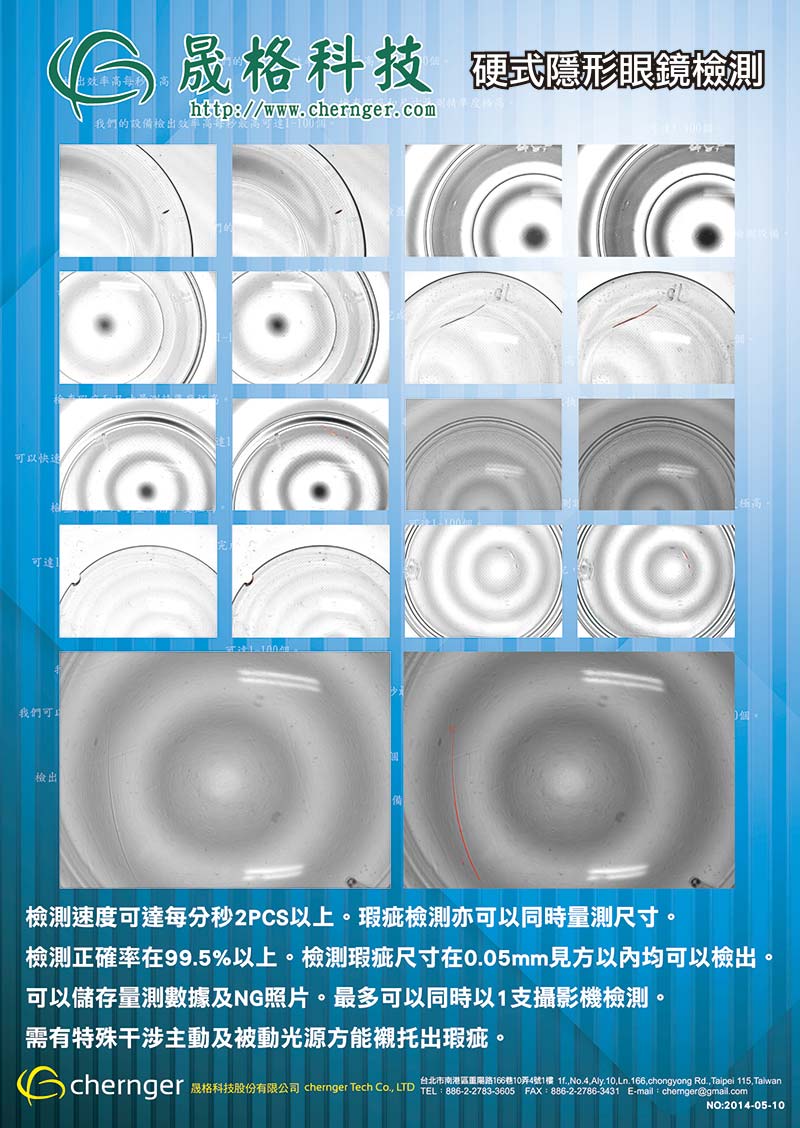

- Hard contact lens inspection

- PP Cup packaging leakage detection

Clients

- 昱嘉(Innova)、亮點(ApexLens)、愛爾康(Alcon)。

Specification

- Camera:12M color industrial camera x4

- Light source: With bright field/dark field, dual light source detection

- Depth of Field: With dual depth of field mechanism, the effective detection depth of field can reach 10 mm

- Lens: 0.5X telecentric Kosaki variable lens

- Inspection speed: 2 pieces per second/720 pieces per minute

- Detection accuracy: 6.9um/pixel

- Detection rate: 95%以上(OK/ NG/)

E-Flyers

Related videos

Contact lens underwater defect detection machine

Dry contact lens inspection machine

.jpg)

.jpg)

.jpg)

.jpg)